At the end of the day it's not enough to say, "We did all that we could."

It is important to be able to say "We did it!"

Primary activities

Welding, assembly, installation and other thermal treatments of metal are all part of our daily tasks. Our longstanding experience, the success of our projects, the quality and timely execution of projects in some of the largest industrial parks in the European Union are the foundation on which we build our future and develop collaboration with all of our clients and partners.

- Quality and professionalism

- Efficiency, timeliness and precision

- Warranty for all work done

- Certified and standardized work processes

- Implementing business processes at the highest safety level

Our technical staff is a guarantee for the timely and professional execution of each project, set up in accordance with the highest quality standards, based on a series of successfully completed projects in pipeline construction and assembly.

The main services of the company are planning and installation of pipelines and steel structures of all kinds and constructing and maintaining chemical and power plants. On the basis of technical drawings and plans, we carry out installation of pipes of all dimensions and other pressure vessels.

- Quality, timeliness and professionalism

- Certified performance

- Quality assurance

Assembly

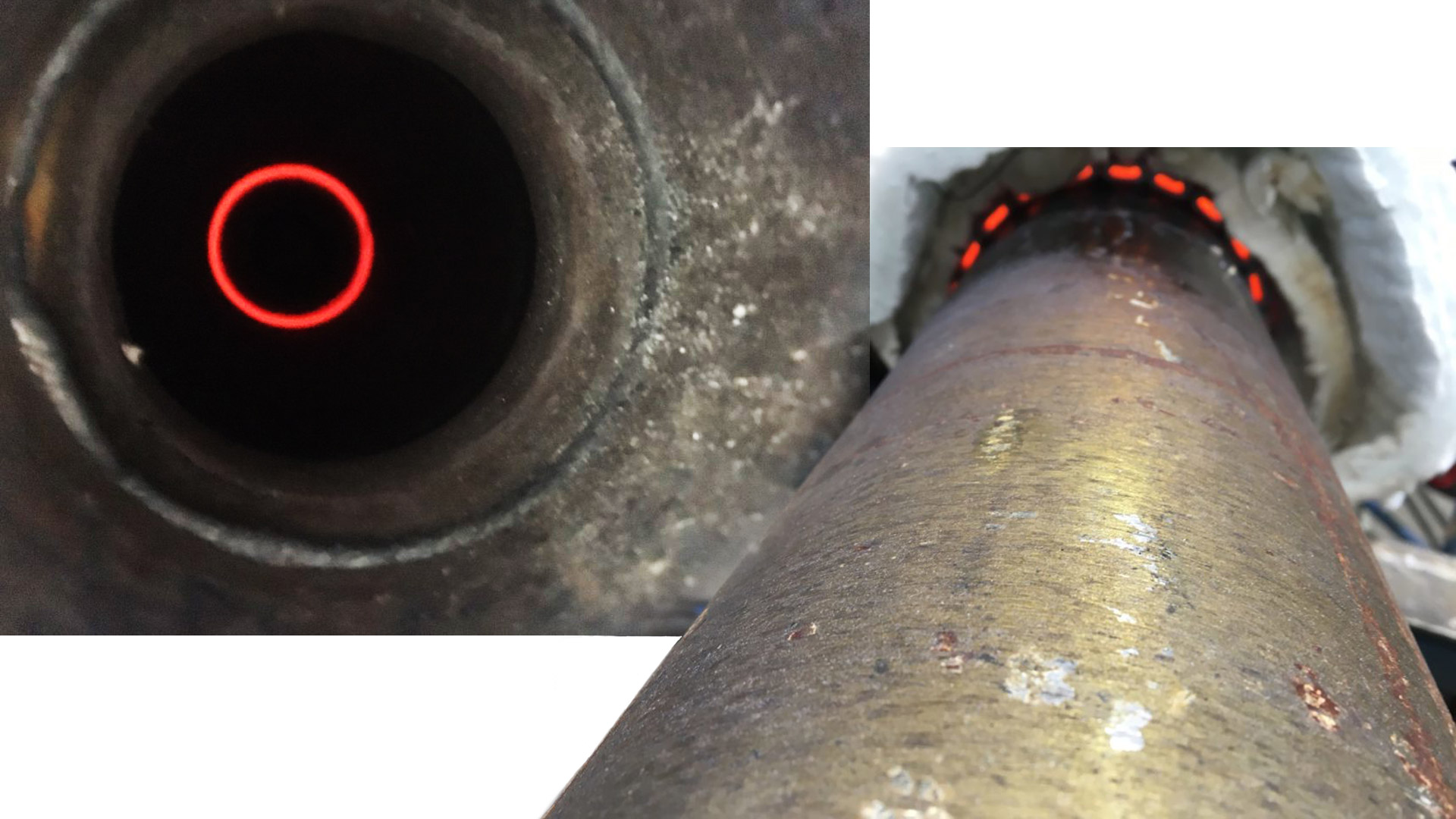

Welding processes

Welding processes represent the basic processes we offer, and therefore the fundamental strength of our business. Regular inspections guarantee low error rates, in accordance with the highest standards of quality, set by our business partners.

All our welders are regularly tested by official bodies and certified to the highest standards of the metal industry.

Welding procedures TIG, TIG/ELEKTRO, MIG/MAG are among our everyday but extremely important tasks. In addition to this, we are also conducting annealing in construction of pipelines on high-pressure lines.

- Quality, efficiency, accuracy and timeliness

- Certified execution of works

- Warranty for all work done

Heat treatment in pipeline construction is a process that prevents later stress in the material. Our expert staff under the supervision of our IWE engineer, also offers a separate and highly competent service, including all the relevant records and documentation of all the completed processes.

- Quality, efficiency, precision and timeliness

- Certified performance

- Mobility of equipment and devices

- Preparing documentation by our IWE manager

- Warranty

Work processes

All our work processes are defined, standardized and certified according to ISO 9001: 2015 and SCC **. Great care is given to protecting the health of our employees and their working environment as well as to environmental protection.

- ISO 9001

- SCC